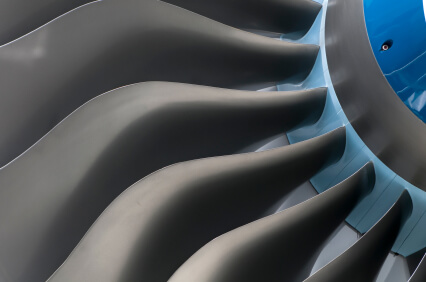

CRDM works with major aerospace organisations to leverage the advantages of

Additive Manufacturing. We have worked on projects ranging from metal satellite

components to UAV flight parts in both test and development phases through to

series production.

We will bring your CAD projects to life by prototyping a variety of aerospace

components in plastics and metals. Using the latest additive manufacturing

processes – we can build parts in 40μm (micron layers) – a quicker and lower cost

alternative to one-off manufacturing using traditional techniques such as machining

from solid.

Recent advances in making metal parts allows us to manufacture components that

are impossible to make using traditional engineering methods; complex channels,

voids and 3D structures are easily included.

Total process material use is substantially reduced as only material required for parts

is used – no swarf.

Examples of our experience

- Building trial and test parts

- Instrumentation fixtures, jigs and assembly aids

- Low volume production parts

- Retrofit components for refurbishment

With strict timelines for interior maintenance and refurbishment programmes when

aircraft on ground and OEM parts with long lead times, often up to 90 days and

parts frequently turning out to be obsolete. CRDM can offer a number of solutions:

- No engineering drawings or CAD required. We can scan parts and produce

- CAD for manufacture

- V0 rated fire retardant materials

- Low volume production with additive manufacturing or mould tooling

- Fast turnaround within days

- Accredited by many leading aerospace companies

How we can help you

We help you cut down the time spent on product development path by manufacturing

prototypes and low volume components from just 3-4 working days – saving weeks

compared to traditional routes.

We can help you regardless where you are in your development – from producing a

one-off prototype item to small run, high-end parts.

What to do next…

Call us now on 08450 514 900 to discuss your project.