Applying the finishing touches

CRDM’s in-house parts finishing service includes a paint shop and a team of highly experienced modelmakers. We can apply most types of paint finishes and supply other specialist finishes including decals, vacuum metalizing, electroplating, anodizing and polishing. Expertly applied to your specification.

To help define the finishing level for a part, CRDM works to a finishing specification system. This ensures that the work is charged for correctly and gives the best value for the customer.

All finishing specifications are made up of 2 parts:

- “A” Surface Finish – visual or important face, typically the outside of a part

- “B” Surface Finish – unseen face of part, usually the inside

The finish grade must be defined for both the “A” and “B” surfaces of a part as below:

We can also easily work to customer supplied drawing if available.

A Guide to SLA 7870 (Transparent) Finishes.

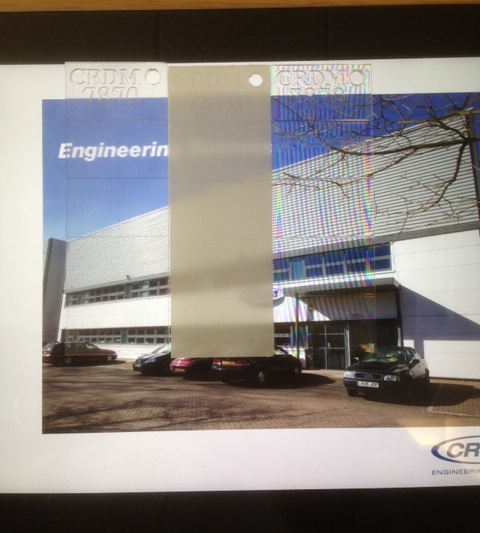

Examples of SLA 7870 Non Finished (Left), C3 Finish (Center) & PP Lacquer (Right) over an iPad screen. Non Finished has visible lines, C3 is frosted and PP Lacquer is the best quality.

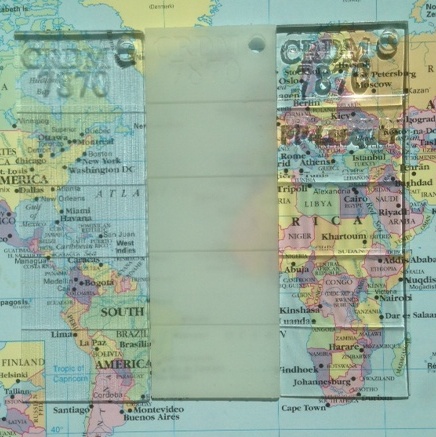

Examples of SLA 7870 Non Finished (Left), C3 Finish (Center) & PP Lacquer (Right) over a printed map. Non Finished has visible lines, C3 is frosted and PP Lacquer is the best quality.

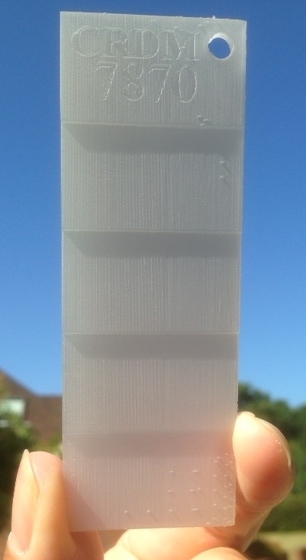

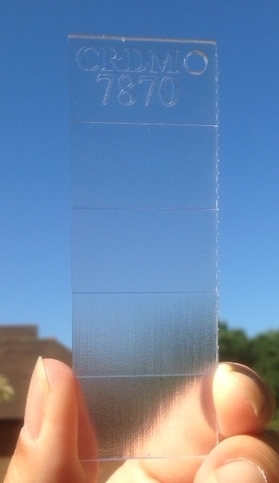

The photo below shows the difference in finish when viewed against natural light…

SLA 7870 C3 finish (shot peened) in natural light…

SLA 7870 – no finishing – please note evidence of the vertical build lines and roughness of the right hand side edge where the support structure was used (now removed)…

SLA 7870 – Polished – PP Lacquered – best possible finish…